South Hill Forest Products Blog

Time to Tap!

Tapping season has begun!

Our students have been working hard to learn the ins and outs of sustainable maple tapping while our CFO, Jason Hamilton, has been monitoring the weather for optimal tapping days.

In the early Spring, increased daytime temperatures paired with freezing temps overnight allow maple trees to begin sap flow as they start to “work“ again after the cold Winter season. This means that tapping when this process begins is the perfect time for harvesting as much sap as possible and making more syrup!

Our students went out to the sugarbush this Wednesday on February 18th, and got their hands dirty in the rain and snow to start our sugaring process. We were able to complete this process with SHFP record-breaking efficiency, and tap 109 maples throughout our sugarbush. For most (if not all) of our students this was their first time watching and participating in tapping, so this is a huge milestone for us!

Now… we wait!

Our next milestone is sap boiling, where we will dive a little deeper into the actual making of our SHFP Maple Syrup. Stay tuned for updates on our timeline and sugaring process as the season continues!

Working with Beeswax!

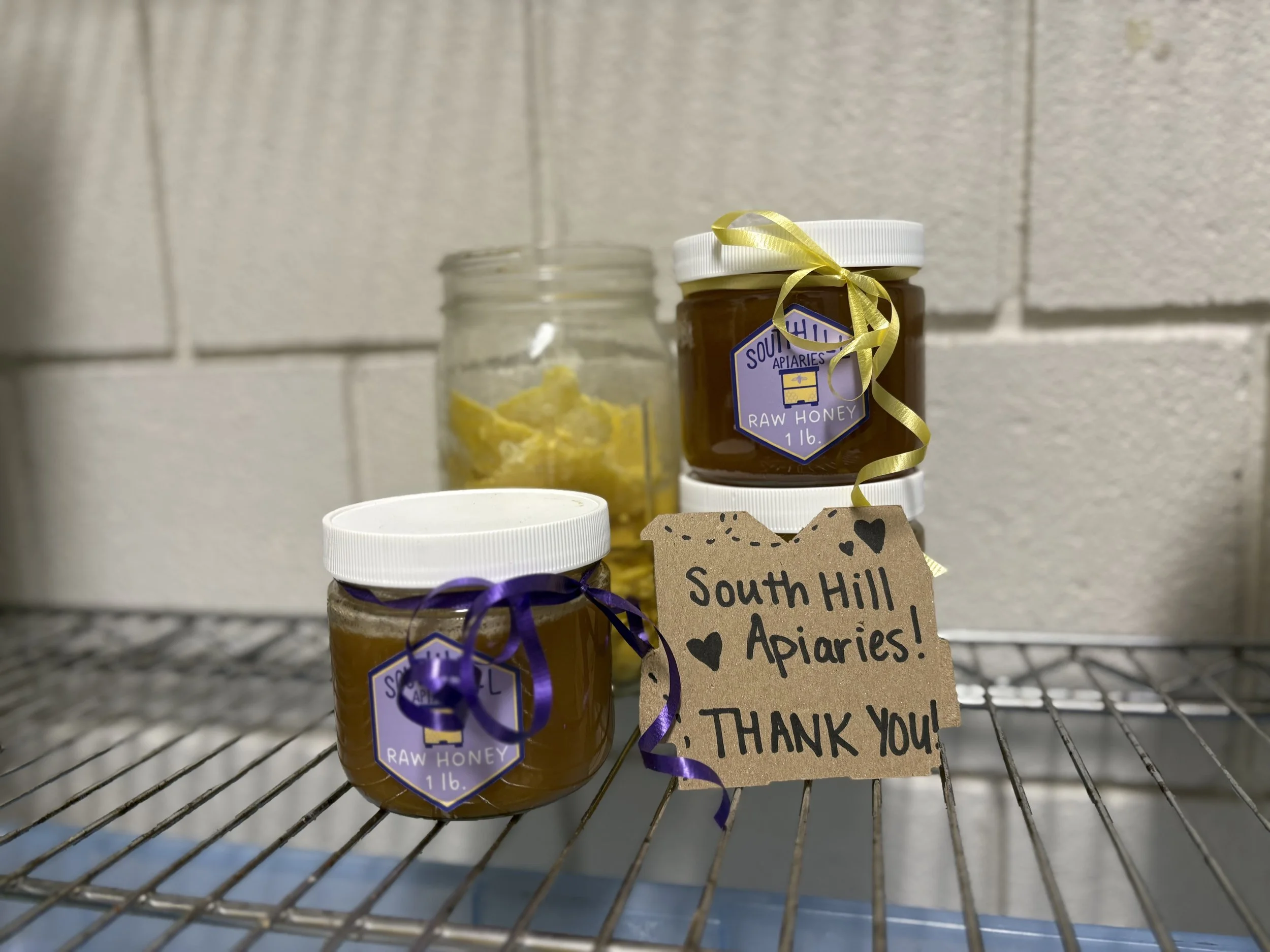

As we begin 2026 production for South Hill Forest Products, our students have begun the process of beeswax candle production! You may be thinking, "what does beeswax have to do with the forest?" To that I'll say: the bees have everything to do with the forest!

Our students who run and maintain South Hill Apiaries have worked hard throughout the Spring and Summer seasons to care for our bee colonies. Part of this process is to harvest the honey and beeswax from our hives of devoted ladies at the end of the season. Side note, male bees don't actually produce honey! They basically reproduce (or not) and die... harsh.

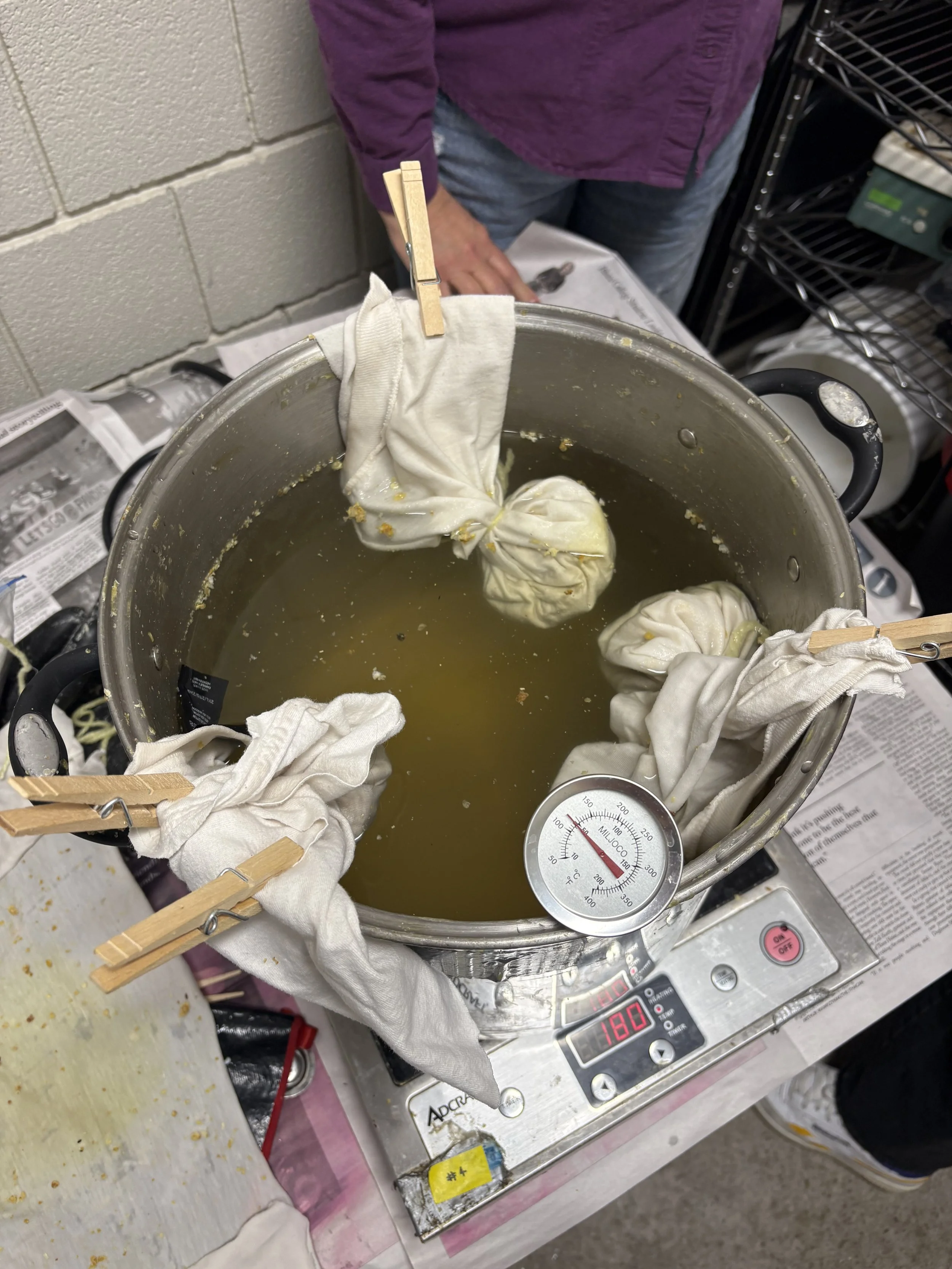

With the harvested materials from our hives, one of our teams of South Hill Forest Products students is planning to make candles, salves, and other beeswax products.To begin this process, our wax must first be rendered. This process entails a series of melting and filtering the wax so that it can be purified. When the wax is extracted from the hives, it may have some leftover honey and other material from the season's other activities stuck in it. While these things are essential for the hive, they aren't great for putting into candles. By melting and filtering the raw wax, we can get rid of all the gunk and come out on the other side with clean, consistent beeswax!

Our Gifts of the Bees team still has a lot of work to be done, but they are excited to keep chugging along with the rendering process. They are stoked to start molding and wicking candles for others to enjoy!

Creating Hand-Carved Wood Products

One of the staple products of South Hill Forest Products are our hand-made wood carvings. Our team has been hard at work, learning proper knife technique to carve utensils like butter spreaders and spoons. We've also had the opportunity to wood burn our own unique designs into our products.

Later this semester, our team will have the chance to further our carving skills through ax-carving. You can learn more about our carving process here.

And you'll be able to purchase some of our lovely hand carved items at our annual open house on April 18!

Introducing the 2026 Team

South Hill Forest Products is back at it! Our new team is super excited to get SHFP up and running for the 2026 season. We’ve been hard at work prepping the labs, dusting off our equipment, and carving our first wooden utensils.

You can meet this year’s team here. Stay tuned for more blog posts throughout the next few months, and be sure to save the date for our annual open house on April 18!