2025 Blog:

Open House ‘25

On April 26, 2025, South Hill Forest Products hosted its annual open house! This is an even hosted annually to celebrate the maple syrup season with pancakes, activities, games, and shopping. The open house also serves to bring the community closer to the forest, answering any questions about our business, syrup, or other products! And who doesn’t like pancakes with delicious maple syrup?!

The whole business worked tirelessly for the past month finishing numerous products like beeswax candles, wooden mushrooms, wooden candle holders, bark baskets, bottle openers, key hangers and so much more.

As we are closing for the season, this year’s students are preparing for new products to possibly be sold some time in the future (some to come next year!). These projects include birch bark baskets, balms, and pine pitch.

Thank you to everyone who came to the event! This was an event that we students in the class will remember forever. We hope to see you again next year!

Indoor Boil

To get the most precise sugar content in our syrup, we finish the boil inside. We took the concentrated sap, filtered it, and continued oiling it in pots in Jason’s lab. We continuously took the brix measurement with the refractometer to get the magic number of 67, when we would then take the syrup off the heat. While some people were stirring the pots, measuring, and filtering, another person on shift would be sanitizing the bottles and then bottling the finished product once it’s ready. We finished with 172 bottles of syrup from the first boil!

Outdoor Boil

The fires are burning and the sap is flowing, this can only mean one thing… it's maple syrup season! It takes a lot of work to get from tree sap to delicious syrup. We collect our own sap to boil our syrup. At South Hill Forest Products, we want to tap maple trees that are healthy so our trees can continue giving sap throughout the years. Additionally, we use a wood fire to boil down the syrup, keeping the sap boiling for a total of 71.5 hours!

Wednesday the 19th, we started to boil our collected sap (around 680 gallons) into syrup! It is a very long and tedious process, but very rewarding. In the woods, we set up our boilers, fire burning hot to get the sap to boil. As the fire continues to evaporate the water, more sap is added. Meanwhile, we filtered and added sap, skimmed the surface, chopped wood, and fanned the fire to make it extra hot. We boiled until the sap reached a certain sugar content, where we will boil the sap a little further indoors to make sure our syrup is extra delicious! Boiling was exhausting, yet rewarding for everyone who can’t wait to share the extra delicious syrup.

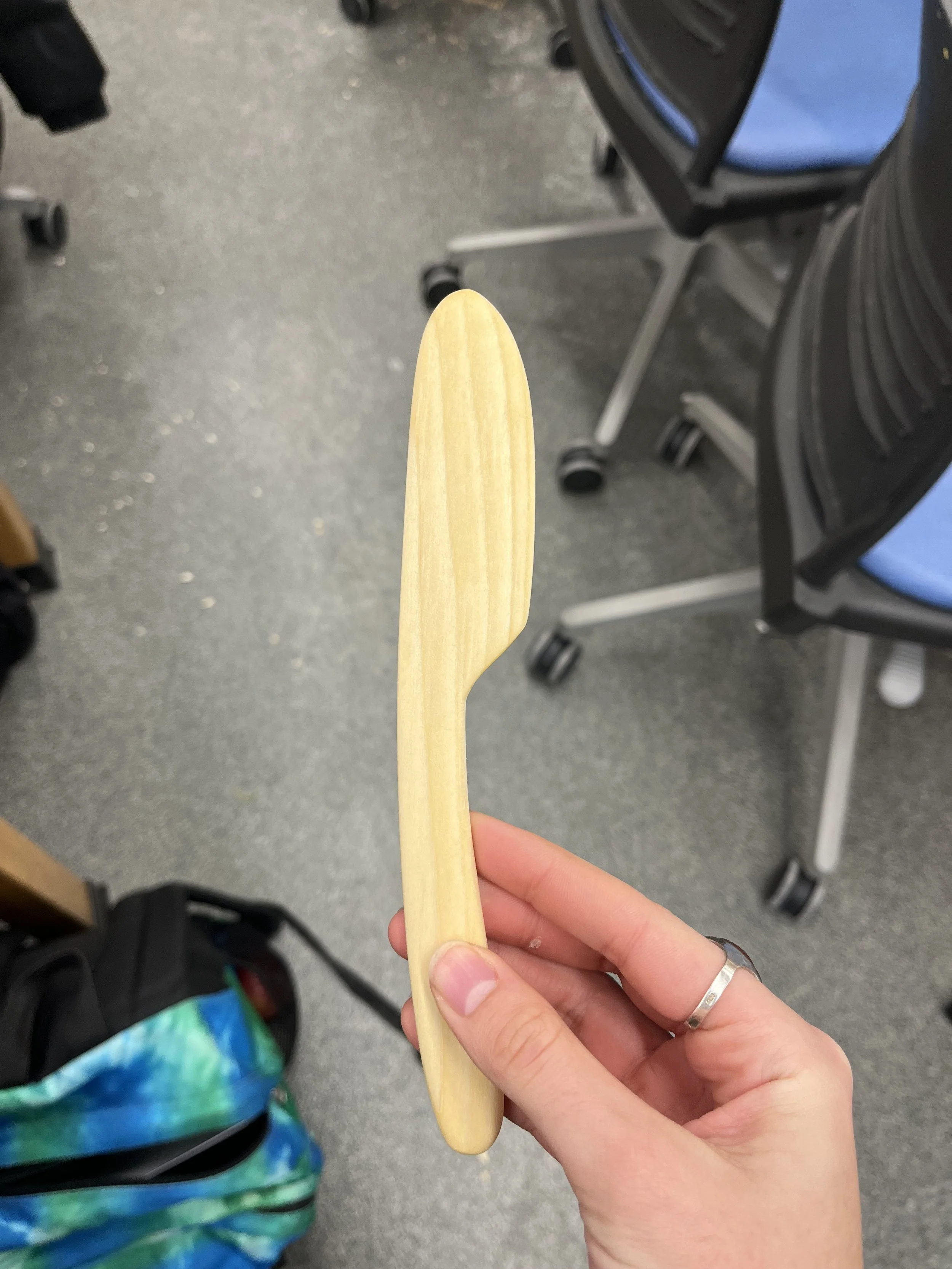

Axe Carving

The past couple of weeks we’ve been learning all about axes - carving with them, chopping wood with them, and appreciating how they are the product of hundreds of years of human ingenuity and innovation modifying this technology to be the most effective it can be for specified or general purposes. We were able to see many of Jason’s axes and use some of them to chop wood out in the sugarbush and carve during class and in his lab. Many students find axe carving more fun than knife carving since you can waste a lot of material much more quickly. We’ve been using axes to start carving butter knives, spoons, and spatulas, and then put the finishing touches on with a knife. In our recent class, Jason brought in some boards that were different types of wood, and we learned about the different aspects of wood of different tree species, like Janka hardness. We examined the boards and got to see and feel the differences between oak, maple, poplar, and pine!

Daily sap checks!

At least once a day, a group of 3+ go out to check on each bin, collect the sap and consolidate it into barrels to be stored until the boil!

First Day at the Sugarbush

This Wednesday, since the weather was consistent for optimal sap flow, we tapped 105 trees! The class split up into teams of four, drilling holes into maple trees, attaching taps and tubing, then feeding this tubing into buckets and covering them to protect collected sap from animals and falling debris. We will be checking sap levels every day from now until the end of maple syrup season, likely sometime in April. We care deeply for the health of our trees, so we took the utmost care in choosing where to drill holes for our new taps, ensuring the least amount of damage to the trees as possible to keep them happy and healthy, providing us with sap for many, many years to come!

Tap and craft

In a matter of less than two weeks, the SHFP crew banded together to create products for Tap and Craft, an event at Hotel Ithaca that features breweries, cideries, and distilleries from the Finger Lakes and beyond, as well as vendors of items such as mugs, soaps, and jewelry. We knew this would be a unique opportunity to showcase our business, but we were on a time crunch. We wanted to create some items to go with the Tap and Craft theme and decided to make and sell bottle openers, flight boards, and coasters. The only slight issue was we had never made flight boards or bottle openers before. Thanks to the hard work of Jason and the students, though, we were able to prototype these new items and have 20 bottle openers and 5 flight boards ready to sell at the event. Also on sale, we had coasters, ornaments, earrings, butter knives, and honey. Attendees were excited and impressed to learn that we’re a student-run business and everything is handmade, so in addition to selling hundreds of dollars worth of products, we also got the word out about how cool South Hill Forest Products is, so all in all, it was a success!

Coasters!

Here are the some wood-burned creations that were previously showcased and sold at Tap and Craft 2025 at Hotel Ithaca.

Introducing The SHFP ‘25 Crew

We’re back! After a one year hiatus due to our CFO being on sabbatical, we’re more pumped than ever to get SHFP back online - check out our updated Meet the Team page and our Instagram @southhillforestproducts to see this year’s crew! In the past few weeks, we’ve formed teams to take on different aspects of the business like marketing, sales, and social media, as well as teams for different product lines like woodworking and gifts from the bees. We have also been reading up on maple syrup in preparation for the boil, and have been learning to carve wooden utensils and woodburn. Jason taught us carving techniques to maximize safety and efficiency with each cut, and students have since made butter knives and spoons!